+86-7996790781 office@chemshun.com

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 15 Author: Pingxiang Chemshun Ceramics Co.,Ltd Publish Time: 2025-11-22 Origin: Pingxiang Chemshun Ceramics Co.,Ltd

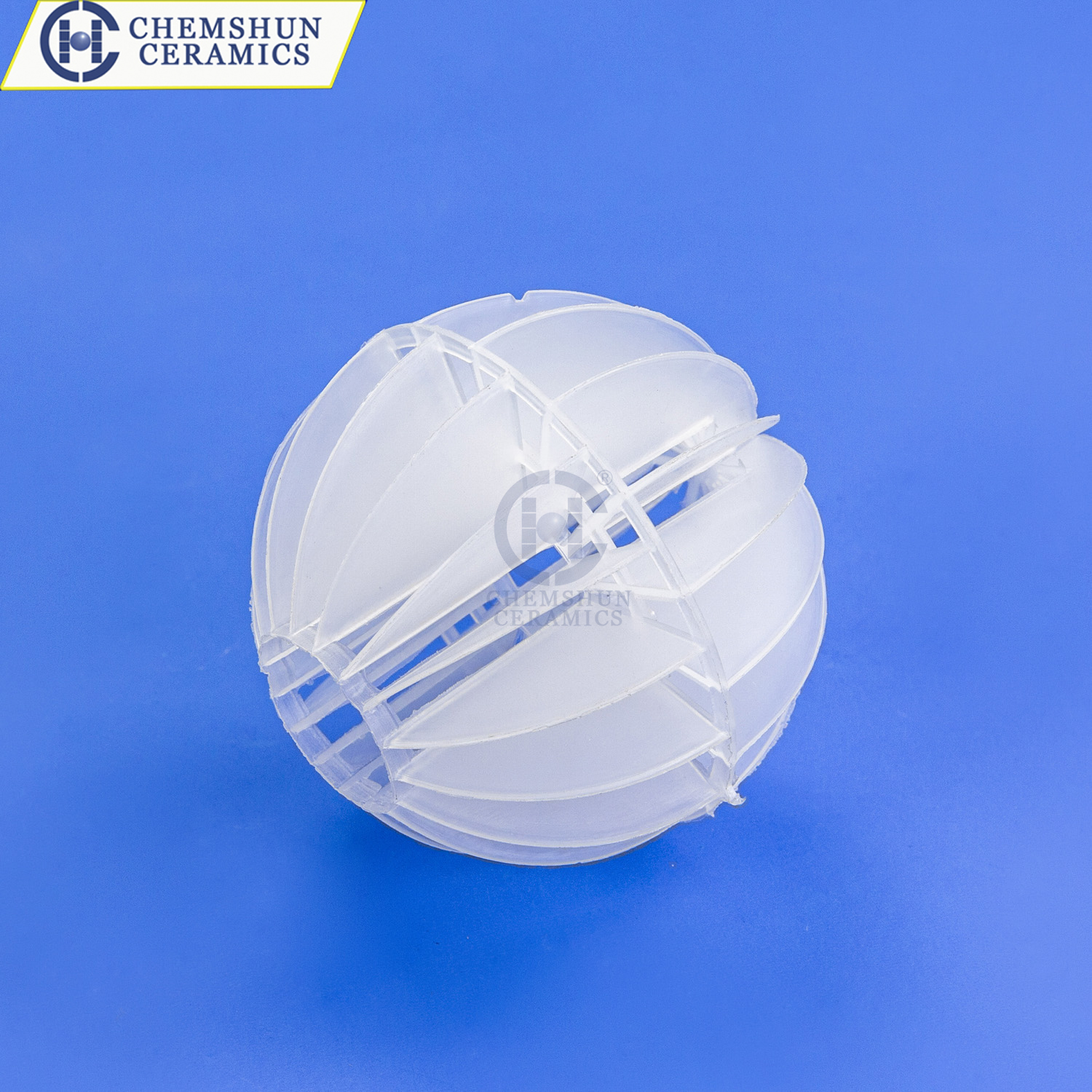

Plastic polyhedral hollow ball packings are highly efficient random tower packings widely used in columns across the chemical, environmental protection, and metallurgical industries. Their structure typically consists of two hemispherical surfaces connected and supported by multiple evenly distributed sector-shaped blades along the central axis. This design creates a vast specific surface area and abundant internal pathways. During operation, liquid forms a film on the blade surfaces, while gas passes tortuously through the voids inside and between the spheres. This provides extensive contact area and turbulent conditions for the gas-liquid phases, significantly enhancing mass transfer efficiency (e.g., in absorption, desorption, distillation). Their hollow structure also ensures low density and lightweight characteristics.

The performance of this type of packing is determined by its key parameters. Common materials include polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC), with operating temperature ranges typically between 60°C and 100°C depending on the material, while some special materials can withstand higher temperatures. Their specific surface area generally ranges from 100 to 500 m²/m³, and the voidage is usually over 90%. This grants them outstanding advantages such as high capacity, low-pressure drop, and strong anti-clogging ability. Compared to traditional packings like Raschig rings, polyhedral hollow ball packings often achieve lower energy consumption and higher separation efficiency under equivalent load conditions.

Polyhedral hollow ball packings packings are primarily used in waste gas purification (e.g., absorption of acidic gases), cooling towers and aeration tanks in water treatment, and distillation columns and scrubbers in chemical production. Their lightweight nature simplifies the installation and maintenance of packing inside columns. When selecting, the most suitable plastic material and size must be determined based on the specific process medium, operating temperature, corrosiveness, and physical strength requirements to ensure the long-term stable and efficient operation of the tower equipment.