+86-7996790781 office@chemshun.com

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2018-01-27 Origin: Site

Mining Wear Plates Improve Operation Efficiency

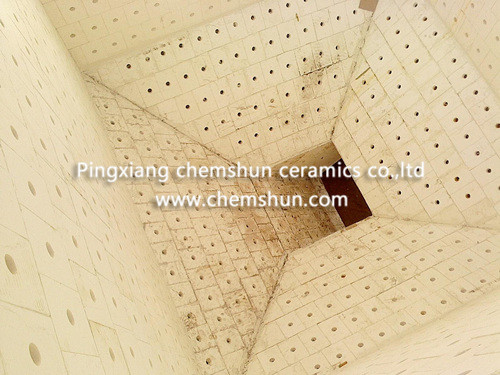

Mine machinery conveys the various objects of ore, coal, rock and sand, severe wear damage often happened during mining, loading and transport, crushing, sorting, upgrading process . so in order to reduce the maintenance cost of mining machine, different mining wear plates are applied as chute liner, hopper liner etc.

So How to choose suitable mining abrasion resistant materials for wear protection ? Chemshun Ceramics as abrasion resistant ceramic manufacturer and supplier professionally offer operation analysis , alumina ceramics design and installation.

Rubber ceramic wear liner is characterized by high impact resistance, easy installation . if handling materials are large particle and high dropping height, fast flow speech. Rubber backed ceramics plate is surely suggested .like chute liner .

Alumina ceramic plain tile and weldable tile liner is common mining wear plate as hopper liner, cyclone liner ,pipe liner etc.

No matter what kind mining wear plates wear applied, it can help industry company to improve production. Also it is more cost effective when you buy a new machines.