+86-7996790781 office@chemshun.com

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 18 Author: Pingxiang Chemshun Ceramics Co.,Ltd Publish Time: 2025-10-23 Origin: Pingxiang Chemshun Ceramics Co.,Ltd

Metal tower packings are widely used in mass transfer, heat transfer, and reaction equipment in industries such as chemical processing, petroleum, and environmental protection. They are suitable for environments with the following characteristics:

1.High Temperature and Pressure: Metal packings exhibit excellent mechanical strength and thermal stability, making them suitable for high-temperature (typically up to 800°C or above) and high-pressure conditions.

2.Corrosive Media: By utilizing corrosion-resistant materials such as stainless steel, titanium, or Hastelloy, metal packings can handle acidic, alkaline, or organic solvent fluids.

3.High Gas-Liquid Loads: The structural design of metal packings reduces pressure drop and enhances mass transfer efficiency, making them ideal for tower systems with high gas-liquid loads.

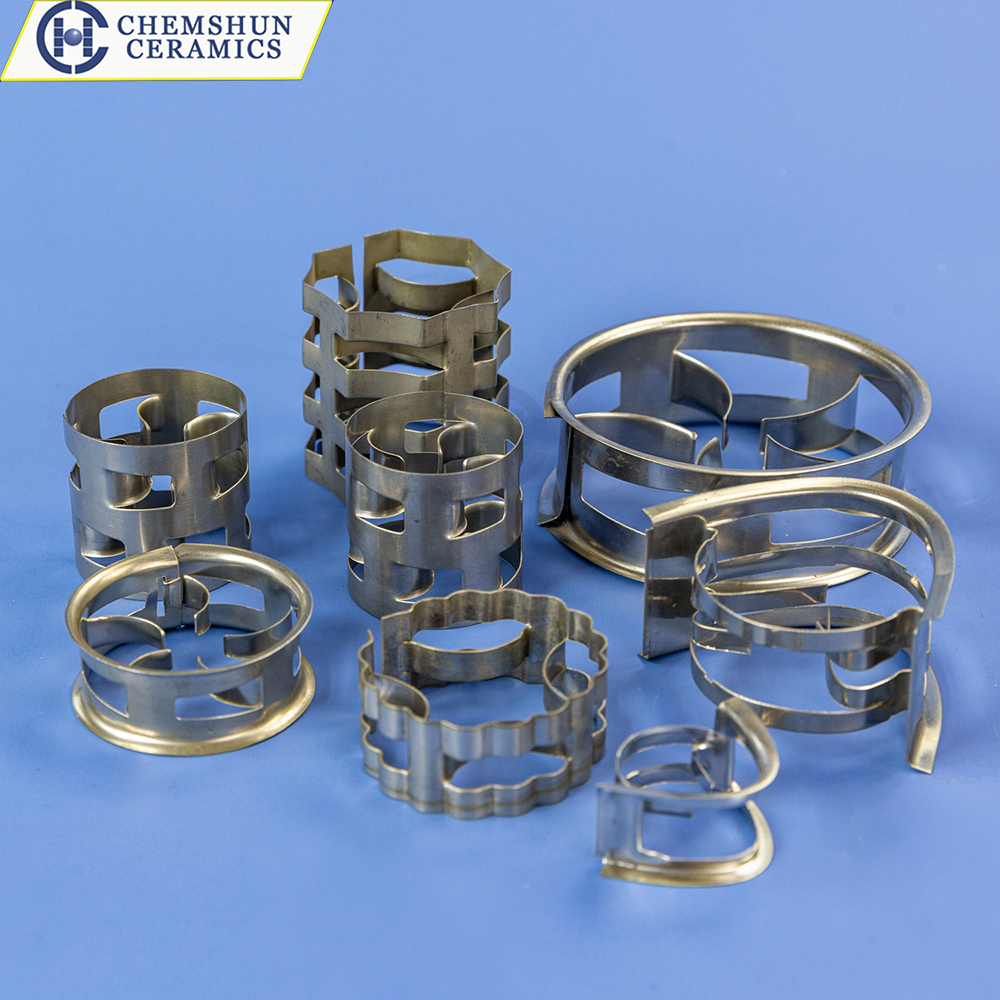

Common types of metal packings include Pall Rings, Staircase Rings, and Conjugate Rings, with the following features:

1.Pall Rings: Featuring windows and inwardly curved blades, they increase specific surface area and gas turbulence, improving mass transfer efficiency by approximately 30% compared to traditional Raschig rings.

2.Staircase Rings: The asymmetric staircase structure disrupts the gas boundary layer, further reducing pressure drop and making them suitable for high-velocity applications.

3.Conjugate Rings: Designed with conjugate curves to optimize liquid distribution and surface renewal, they combine high processing capacity with strong anti-clogging performance.

In applications such as exhaust gas treatment, distillation columns, and absorption towers, metal packings are the preferred choice due to their durability and adaptability. Proper selection can significantly enhance system energy efficiency and operational stability.