+86-7996790781 office@chemshun.com

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Chemshun Ceramics Publish Time: 2024-04-15 Origin: Pingxiang Chemshun Ceramics CO.,LTD

1 Introduction

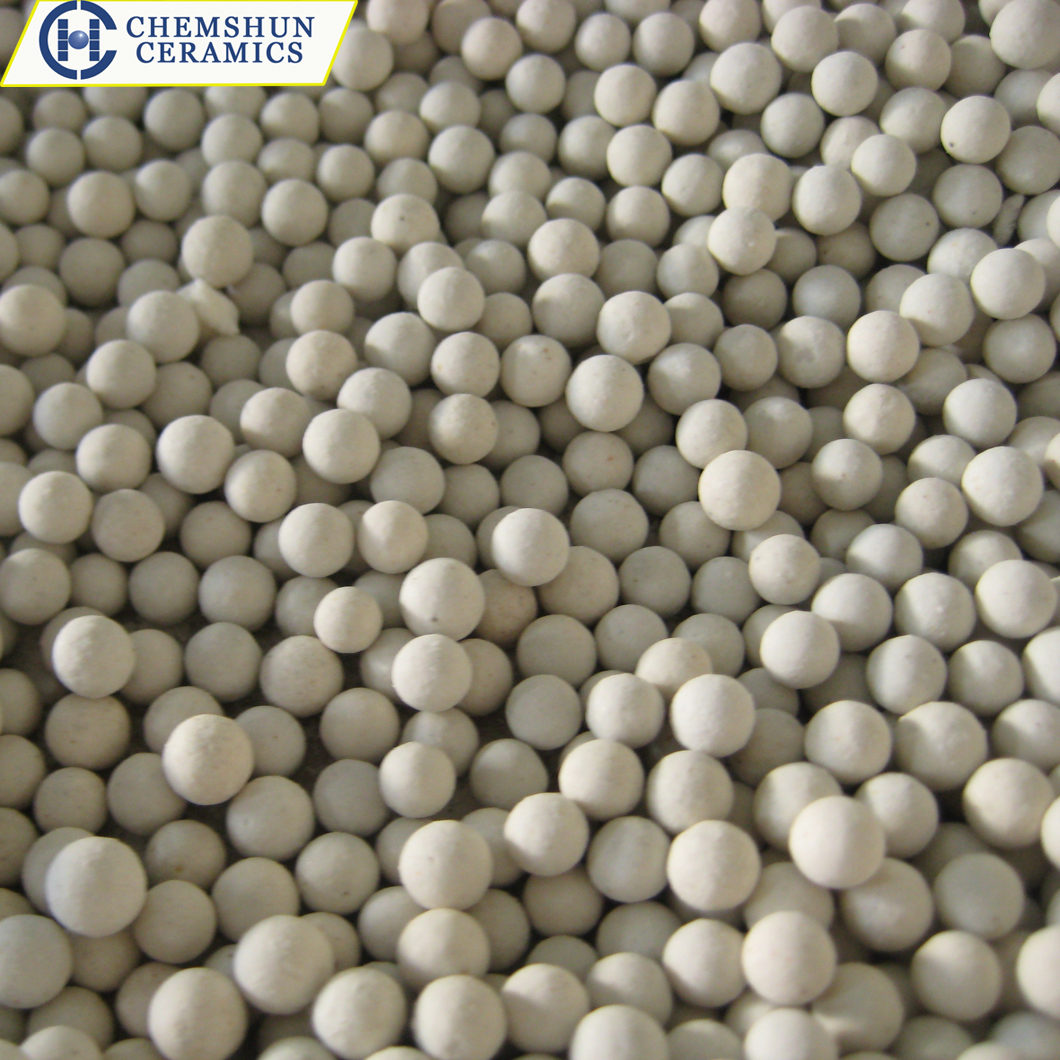

Inert ceramic balls are spherical fillers made of high-purity inert ceramic materials with excellent chemical stability, thermal stability and wear resistance. Due to their high mechanical strength, low water absorption, high corrosion resistance and low thermal expansion coefficient, inert ceramic balls are widely used in many industrial fields.

2:Application areas:

Inert ceramic balls are widely used in reactors, packed towers, adsorption towers, ion exchangers and other equipment in chemical, petroleum, environmental protection, food, pharmaceutical and other industries to improve mass transfer efficiency, promote chemical reactions or serve as catalyst carriers use.

3. Precautions for use

1)Transportation and Storage**: Inert ceramic balls should be handled with care during transportation to avoid falling and collision. When storing, you should choose a dry and ventilated warehouse to avoid prolonged exposure to moisture or high temperature.

2) Installation and Replacement**: When installing or replacing inert ceramic balls in equipment such as packed towers, operating specifications should be followed to ensure that the equipment has good sealing and avoid gas or liquid leakage.

3)Cleaning and Maintenance**: Clean the inert ceramic balls regularly to remove impurities and dirt accumulated on the surface to maintain stable performance. When cleaning, you should choose an appropriate cleaning agent and avoid using chemicals such as strong acids and alkalis that may cause damage to the ceramic balls.

4)Inspection and replacement cycle: Regularly check the integrity and performance of the inert ceramic balls. If they are damaged or have reduced performance, they should be replaced in time. The replacement cycle should be determined based on the actual usage and usage environment. It is generally recommended to perform a comprehensive replacement every 3-5 years.

5)Safety Protection: When handling inert ceramic balls, appropriate protective equipment, such as gloves, masks, etc., should be worn to avoid skin contact or inhalation of dust due to accidents. At the same time, the work area should be kept tidy to avoid safety risks such as clutter accumulation and tripping.

In summary, inert ceramic balls, as a high-performance filler material, need to pay attention to handling, storage, installation, cleaning, inspection and other aspects during use to ensure stable performance and safe use. With correct use and maintenance, inert ceramic balls can play an important role in multiple industrial fields, improving equipment operating efficiency and production efficiency.